EN 13084-7:2012 Free-standing chimneys Part 7: Product specifications of cylindrical steel fabrications for use in single wall steel chimneys and steel liners.

EN 13084-7:2012 独立式烟囱 第7部分:圆柱形钢捏造的产品规格为单壁钢烟囱钢内衬使用

EN13084-7烟囱产品CE认证强制时间

EN 13084-7标准已经于01/09/2013开始强制。相关产品加贴CE标识,才能在欧洲市场范围内销售。

烟囱产品CE-CPR认证根据EN 13084-7准进行认证。

EN13084-7烟囱产品CE认证产品认证法规及体系

EN 13084-7烟囱产品CE认证根据欧盟建筑产品CPR法规,采用体系2+产品认证体系(AVCP System 2+)。

从2013年7月1日起,欧盟强制实施建筑产品CPR法规(Construction Product Regulation简称No.305/2011/EU-CPR法规) ,新的CPR法规取代之前的CPD指令(Construction Product Directive简称CPD:89/106/EEC指令) ,我们为欧盟公告号机构的授权合作机构,可为您提供专业权威的建筑产品CE认证。

EN 13084-7钢质烟囱CE认证标准适用范围

The European Standard (EN 13087) deals with steel products for single wall steel chimneys and liners which are produced either in series or single items. It is a product standard which specifies the performance requirements of cylindrical steel fabrications for use in single wall chimneys and steel liners for free-standing chimneys used to convey the flue gas to the outside atmosphere. It also specifies the requirements for insulation and cladding being part of the single wall steel chimney and liner. It provides for the evaluation of conformity of single wall steel chimneys and liners to this European Standard.

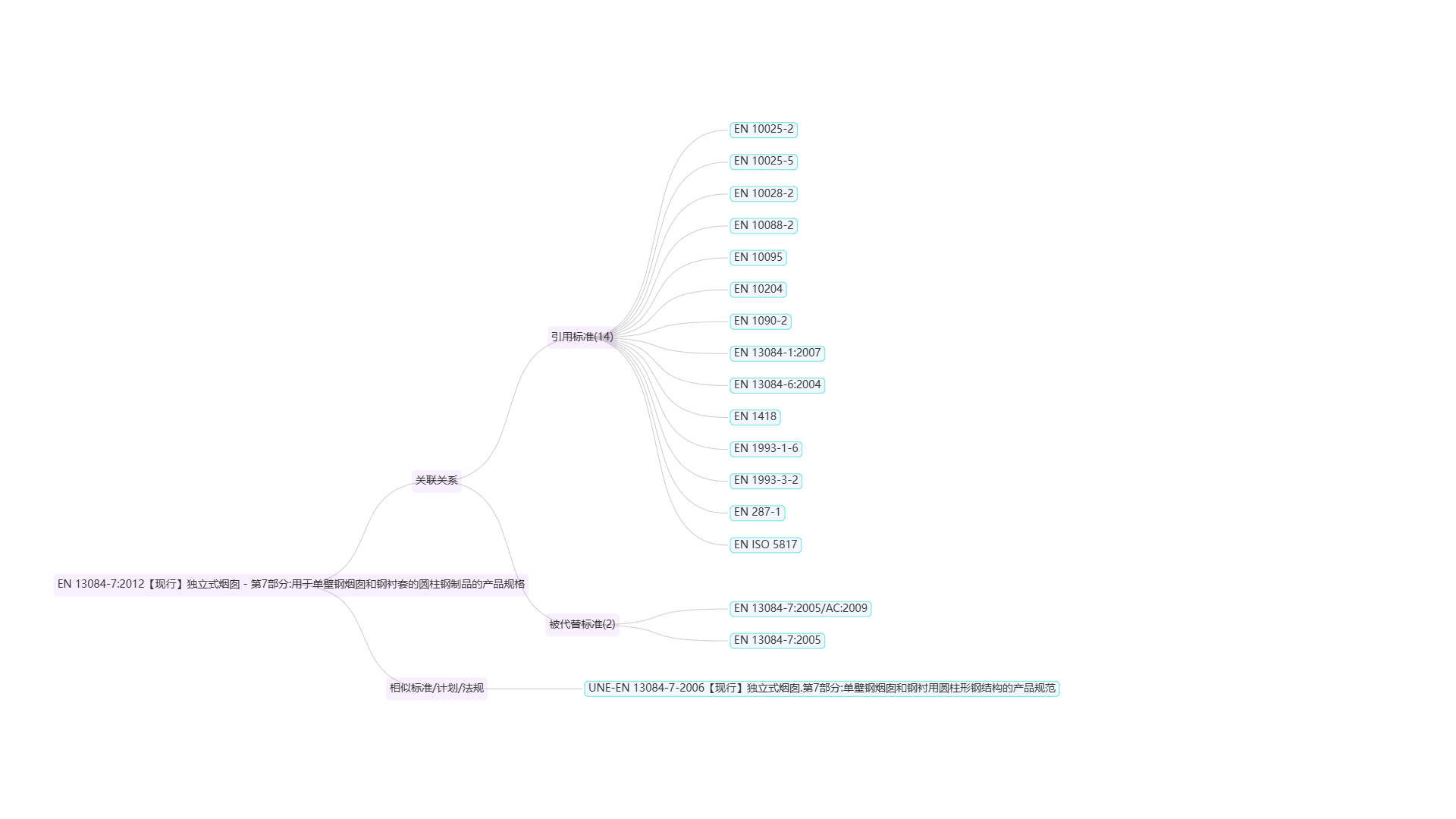

EN 13084-7与其它标准的关联关系

EN 13084-7认证主要检查项目

| Clause | Title / requirement | Finding | Compliant Y / N | Non-conformity Reference No. | ||

| 1 | General | |||||

| 1.1 | Who is the person responsible for the factory production control system? How is he / she integrated into the organisation? For example, organisation chart, responsibility matrix, job descriptions or qualification profiles | |||||

| 1.2 | Correctness of marking and labelling? (ZA.3) | |||||

| 1.3 | Which temperature classes are applied to the chimneys? (8) | |||||

| 1.4 | How is the product designation applied? (9) | |||||

| 2 | Initial inspection of factory | |||||

| 2.1 | Are records available to show that initial type testing has been performed on: check of calculations and drawings; raw materials; welding procedures; and qualification of welders? (7.1.1) | |||||

| 2.2 | Are the in-plant facilities sufficient and suitable for the planned area of application? | |||||

| 2.3 | Are plans available for the maintenance of the facilities? | |||||

| 2.4 | Is it ensured that damaged facilities are not utilised? | |||||

| 2.5 | How is certified steel material stored and identified? How is the traceability to the Inspection certificate? (7.2.2) | |||||

| 2.6 | How are welding consumables stored and identified? How is the traceability to the Inspection certificate? (7.2.2) | |||||

| 2.7 | What welding processes are applied? | |||||

| 2.8 | Are welding procedure specifications (WPS) available for the applied welding procedures? | |||||

| 2.9 | How are these welding procedures qualified? | |||||

| 2.10 | How is it ensured that non-qualified welders do not weld on the cylindrical components for the chimneys? | |||||

| 2.11 | How is the traceability between actual welds, WPS and welder? | |||||

| 2.12 | Which methods of NDT are applied on the welds? | |||||

| 2.13 | Non-conforming products (lack of compliance and corrective measures) | |||||

| 2.14 | Have measures been stipulated for ‘how to proceed in the event of a lack of compliance with stipulated requirements’? For example: – marking – responsibilities – repair procedure specification / repair – repeat test – measures in order to prevent any reoccurrence | |||||

| 3 | Factory production control | |||||

| 3.1 | How is the FPC- system documented? (7.2.1) Does the FPC system consider the following characteristics; Soot fire resistance per EN 13084-6: 2016Prescriptions for welding in accordance with EN 13084-6Fluid dynamic calcs. per EN 13084-1: 2007Temperature classesStatic calcs.Resistance against chemical attack | |||||

| 3.2 | Are material records available? (7.2.2) a) Steel inspection certificate 3.1 acc. EN 10204: 2005, b) Welding consumables – inspection certificate 3.1 acc. EN 10204: 2005, c) Structural bolting with CE marking, and d) Insulation – declared values by manufacturer | |||||

| 3.3 | Qualification of the welders acceptable? (7.2.3) a) Manual welder acc. EN 9606-1:2017, and b) Mechanical welder acc. EN ISO 14732:2013 | |||||

| 3.4 | Welding quality control applied? (7.2.4) a) is welding visually inspected in accordance with EN ISO 5817: 2023? b) is an inspection report issued? | |||||

| 3.5 | Coatings acceptable? (7.2.5) Is a letter of conformity available containing: a) paint manufacturer and batch numbers, b) surface preparation, c) ambient and treated surface temperature, d) ambient air humidity, e) average dry film thickness. | |||||

| 3.6 | How are critical geometrical dimensions checked and recorded? (7.2.6) | |||||

| 4 | Parameters related to all relevant characteristics of Table ZA.1: | |||||

| 4.1 | Resistance to fire (4.2.2) | |||||

| 4.2 | Gas tightness / leakage (4.2.3) | |||||

| 4.3 | Flow resistance (4.2.4) | |||||

| 4.4 | Dimensioning / thermal resistance (4.2.5) | |||||

| 4.5 | Thermal shock resistance (4.2.6) | |||||

| 4.6 | Resistance to wind load ( 4.2.1) | |||||

| 4.7 | Flexural tensile strength (4.2.1) | |||||

| 4.8 | Compressive strength (4.2.1) | |||||

| 4.9 | Resistance to freeze-thaw (4.2.7) | |||||

| 4.10 | Durability of gas tightness / leakage against chemicals / corrosion (4.3; 5) | |||||

| 4.11 | Durability of flexural tensile strength against chemicals (4.3; 5) | |||||

| 4.12 | Durability of compressive strength against chemicals (4.3; 5) | |||||

| 4.13 | Dangerous substances (4.4) | |||||

如需更多资讯,欢迎联系我们:

服务热线:021-52992565

电子邮箱:info@certpi.com